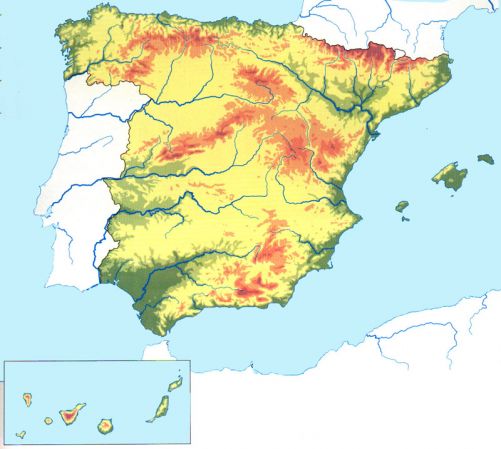

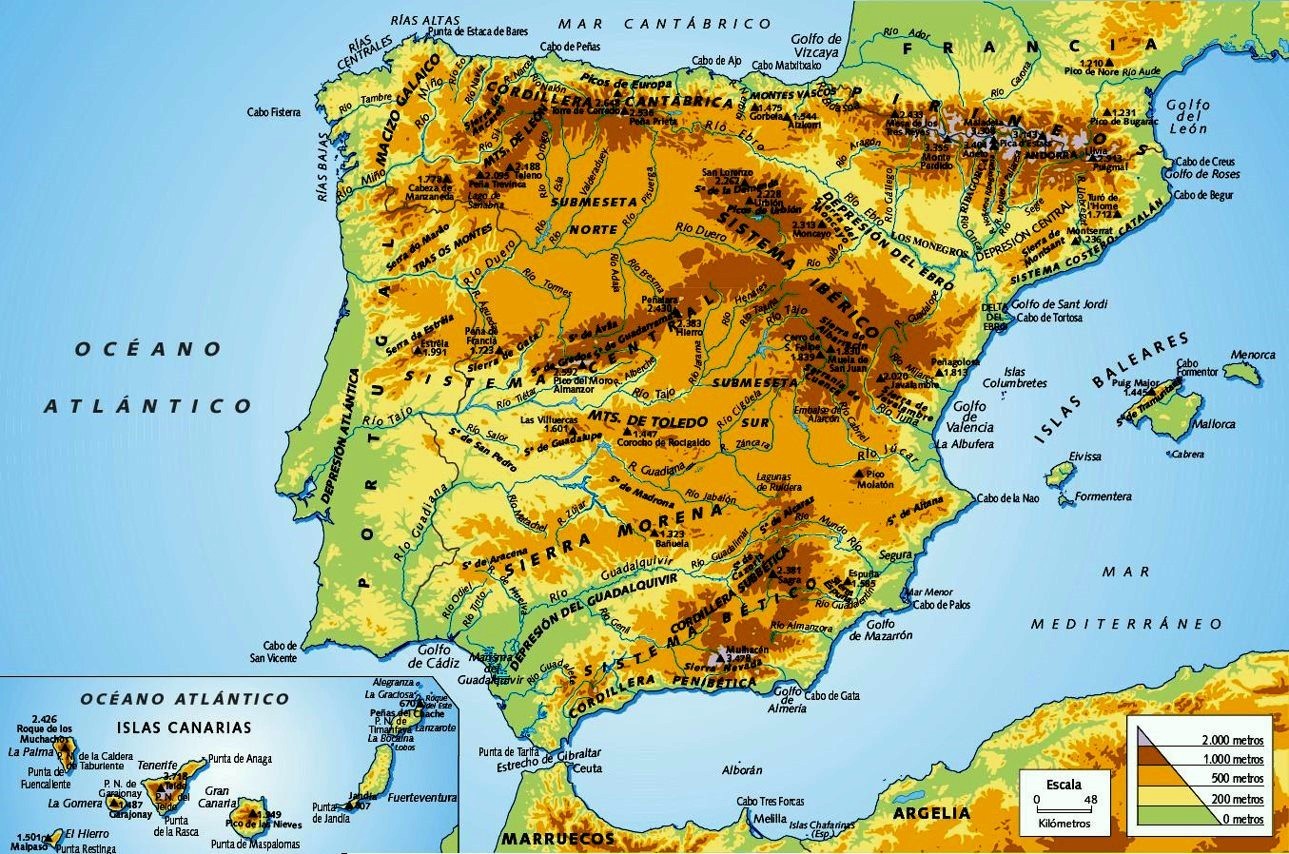

1.-EL RELIEVE DE ESPAÑA.- El territorio de España comprende buena parte de la península Ibérica, las islas Baleares, las isl

Relieve de España: ideas para trabajar en clase, mapas gratuitos para imprimir y juegos | Una profe en tu mochila

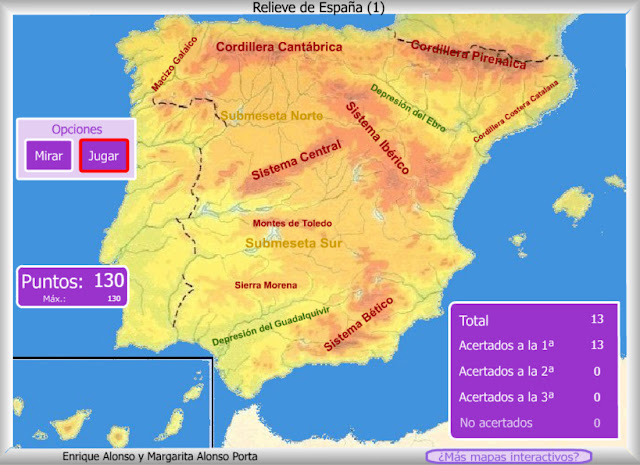

ALGARGOS, GEOGRAFÍA DE ESPAÑA: MAPAS PARA PRACTICAR LAS LOCALIZACIONES DE LAS PRINCIPALES UNIDADES DEL RELIEVE Y LOS RÍOS DE ESPAÑA. Mapas Flash de Enrique Alonso.

Relieve de España: ideas para trabajar en clase, mapas gratuitos para imprimir y juegos | Una profe en tu mochila

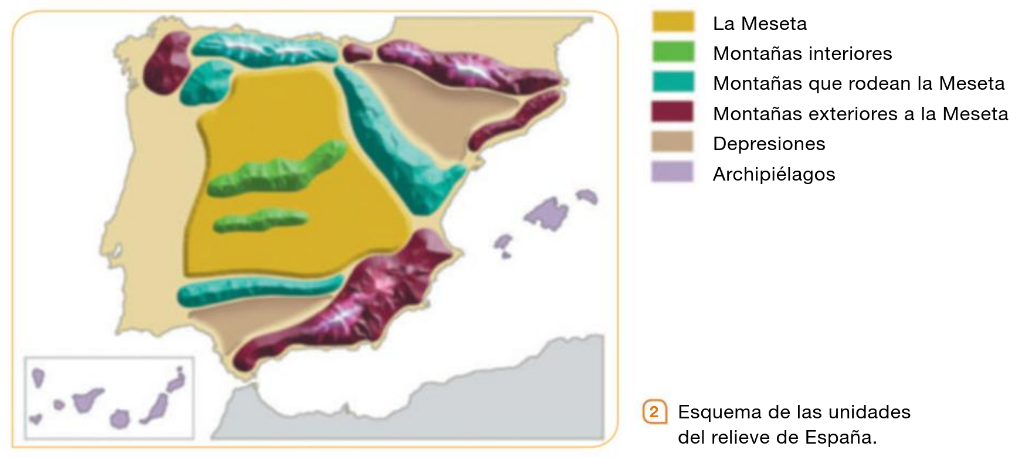

El mapa muestra, de manera más esquemática, las unidades de relieve de la Península. | Mapa fisico de españa, Relieve españa, España

![Unidades de relieve de España [Ciencias Sociales] ~ Optifutura Unidades de relieve de España [Ciencias Sociales] ~ Optifutura](https://blogger.googleusercontent.com/img/a/AVvXsEhBNj6pBTzeX8y7liBjt95d0r74L8DiXhgtjwC1xEsEJ9U5Ol5_o_K_EE8aBo7prC581i-u96ghvQ3-yCDLtP48vxVH4hxTzA-Xyhx7sPVhQqgz4g4g_J8TE7uSlQVrQsbqegxpCUMqQLpUHlmc-b4Yy9ghgTTczqgHVoF-CW8MU1RjSkJN_isKCwj4hA=w400-h278)